Ammonia pipelines: existing networks, future deployments, and safety considerations

By Kevin Rouwenhorst on June 26, 2025

In our June Episode of Project Features, Hans van ‘t Noordende from ISPT and Megan Acker from Sunoco LP discussed ammonia transportation via pipelines, both in northwest Europe and the US Midwest. The recording is available here, and you can also download the speaker presentations.

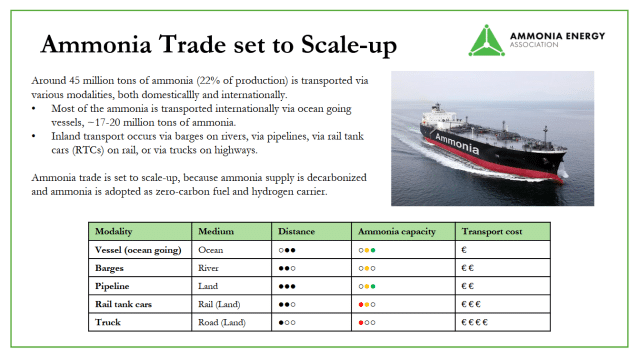

Ammonia transportation modalities

Click to enlarge. Ammonia transport modes, including distance, capacity and cost. From Kevin Rouwenhorst, June 2025 Project Features introduction.

Every year, around 45 million tons of ammonia (equivalent to 22% of global ammonia production) is transported domestically and internationally, utilizing various transport modalities. A large portion of this, around 17 to 20 million tons, is transported via ocean going vessels, typically Midsize Gas Carriers (MGCs) with around 37,000 m3 or 25,200 tons of ammonia capacity. Inland ammonia transport occurs via barges on rivers, via underground pipelines, via rail tank cars (RTCs) on rail, and last-mile delivery is sometimes done via trucks on highways.

Ammonia trade is set to scale-up, as ammonia supply is decarbonized for existing markets and ammonia is adopted as zero-carbon fuel and hydrogen carrier. A scale-up of ammonia transportation inland will be required, with ammonia pipelines especially suitable for high capacity transportation. Ammonia transportation in pipelines is typically pressurized, using low alloy carbon steel pipelines.

Various long-distance ammonia transportation pipelines are currently in operation. The United States has one operational ammonia pipeline, connecting 7 states in the US Mid-West, and transporting 1.5 million tons per year. Mexico also operates one ammonia pipeline, connecting the Gulf of Mexico and the Pacific Ocean. Europe has various short-distance ammonia pipelines, the longest being a 74 km route located in Italy, transporting 0.3 million tons per year.

New ammonia pipelines are also being considered, connecting new demand centres and new production locations. A long-distance ammonia pipeline may be constructed from The Netherlands to Germany for energy uses and industrial uses. In 2025, a 300 km pipeline was announced between renewable ammonia production in Chifeng City and Jinzhou Port in the North-East of China.

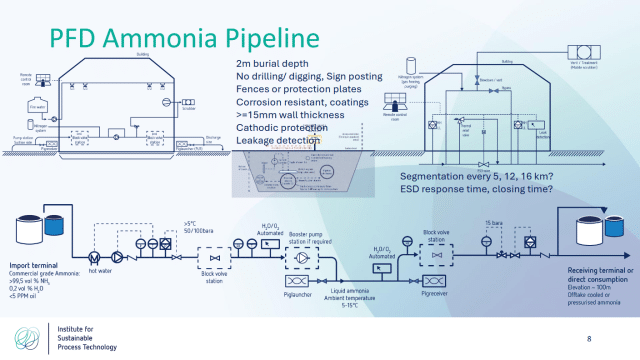

Safe design of an ammonia pipeline in the Netherlands and Germany

Germany and northwest Europe have set ambitious goals for future energy imports, with ammonia set to play a significant role. But, as well as acting as a hydrogen carrier, ammonia imports can be transported further inland once they arrive in the EU, with a variety of potential applications and customers located in interior industrial hubs.

The Institute for Sustainable Process Technology (ISPT) has recently published a report evaluating the techno-economic feasibility of a new ammonia pipeline from the Port of Rotterdam in the Netherlands to Germany (about 550 km, trajectory comparable to the proposed Delta Rhine Corridor), connecting a key coastal, import site with industrial locations in Germany’s interior. The pipeline in the study is designed for an annual flow capacity of 7 million tons of ammonia.

Click to enlarge. Process Flow Diagram of the proposed ammonia pipeline in northwest Europe. From Hans van ‘t Noordende, Ammonia Pipeline Safety (June 2025).

The ammonia pipeline would be an alternative to existing ammonia transportation modalities such as barges and railcars. The ISPT report details the best available technology for safe pipeline operations over long distances, including infrastructure such as pumping stations. The import terminals in the Port of Rotterdam, and the receiving terminals are also included in the study. In the study scenario, ammonia is stored as a liquid at around -33°C in large, atmospheric pressure storage tanks. Pressurization of the liquid ammonia to 50 bar is required for the pipeline, as well as heating to above 5°C (to prevent freezing). Inherently safe design practices are chosen with state-of-the-art design, although guidelines for these are currently not available in Europe.

Pumping stations, diameter, segment lengths: impacts on loss of containment scenarios

Due to the relatively short length of existing ammonia pipelines in Europe, intermediate pumping stations are typically not required. However, the ISPT study envisages a pipeline length that would require intermediate pumping stations, to maintain a pressure of 50 bar throughout the length. The pipeline diameters for both scenarios (with and without intermediate pumping stations) were calculated via a hydraulic analysis, indicating that a scenario with intermediate pumping stations decreases the ammonia “line inventory” by a factor 3 due to a smaller diameter of 20” (instead of 32”). This decreases the potential ammonia release in case of a loss of containment scenario – an inherently safer option.

Safeguarding of thermal expansion between segments is required, with block valve stations in between pipeline segments. ESD (emergency shutdown) valve stations are designed for a fast response time. Current codes in Europe do not specify the exact locations between valve stations. ESD valve distances of 5 km, 12 km, and 16 km were evaluated. Although the initial cloud formation would be similar, a pipeline segment of 5 km would have zero pipeline inventory remaining after 30 min (i.e. all ammonia in the segment released), while 12 km and 16 km segments have 47% and 60% of the ammonia pipeline inventory remaining.

Risk mitigation

ISPT details a number of methods for risk mitigation in the study pipeline. Although no current guidelines for ammonia pipeline best-practice are available for Europe, lessons and standards used in relevant industry sectors (and other jurisdictions) have been incorporated, including:

- 2 m burial depth (versus 1.2 m or 1.5 m for natural gas pipelines)

- No drilling/digging near the pipeline indicated by sign posts

- Fences or protection plates for accidental digging in urban areas

- Where possible, routing the pipeline outside urban areas, to prevent rather than mitigate risks

- Corrosion resistant coatings

- At least 15 mm pipe wall thickness

- Cathodic protection

- Leakage detection

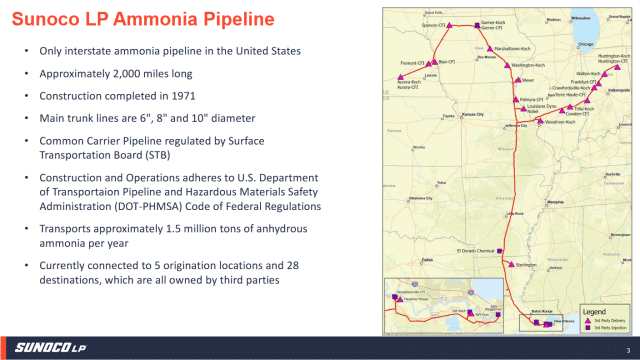

Operational aspects of an operating ammonia pipeline in the US Midwest

Click to enlarge. The Sunoco LP Ammonia Pipeline Trajectory. From Megan Acker, Ammonia Pipeline (June 2025).

In the United States, Sunoco LP (previously NuStar) operates a liquid ammonia pipeline connecting seven states in the US Midwest, servicing agricultural and fertilizer customers, mainly through rural areas. 1.5 million tons of ammonia are transported along the network every year, with 5 origination locations and 28 destinations. The pipeline was completed in 1971, and covers about 2,100 km along the main line, and 650 km via the side line. The pipeline diameters along the main line are 6”, 8”, and 10”, with 17 active pump stations along the line, as well as flow meters at origin locations and destinations to measure product flows. The maximum operating pressure in the system is 1,340 psig (92.4 barg), with a temperature in the range of 35 Fahrenheit (1.7°C) and 85 Fahrenheit (29.4°C).

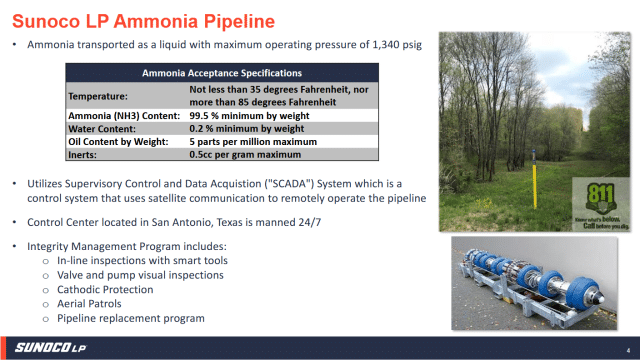

Click to enlarge. Inspections for the Sunoco LP Ammonia Pipeline. From Megan Acker, Ammonia Pipeline (June 2025).

Sunoco LP has a remote control center located in San Antonio, Texas to oversee the whole pipeline, using a Supervisory Control and Data Acquisition (SCADA) system connected via satellite communication. Valves can be remotely opened and closed from the control center, which is manned 24/7. A back-up control center also exists, which is tested quarterly.

The Integrity Management Program is based on the decades of operational experience and includes:

- In-line inspections with smart tools (every testable segment is tested with these smart tools at least every 5 years, an ongoing program)

- Valve and pump visual inspections (by field operators in close proximity to pipeline)

- Cathodic Protection

- Aerial Patrols (every 2 weeks, a pilot is flying above the trajectory markers to check for any change of vegetation that may indicate a compromise to the pipeline. Also in constant communication with the field operators. )

- Pipeline replacement program (based on smart tools analysis, prioritizing pipeline segments that need to be replaced)