Emission performance of ammonia-fueled, two-stroke marine engines

By Kevin Rouwenhorst on May 06, 2025

Click to expand. The ammonia-fueled maritime propulsion landscape. Source: Ammonia Energy Association.

In the lead up to its historic 83rd meeting this April, the IMO’s MEPC (Marine Environment Protection Committee) published a “Review of current literature on tank-to-wake nitrous oxide emissions from ammonia-fueled engines”. The literature review is intended to assist MEPC member states and GESAMP (the IMO body working on LCA guidelines for zero and near-zero marine fuels) to prepare and assess proposals for default emission factors. Historically, experimental data regarding emissions from ammonia-fueled two-stroke engines was not widely available, with emission data mostly from smaller-scale research engines.

With the release of this review – and public announcements from several of the key ammonia engine manufacturers – we are now able to better understand and anticipate the emission performance of ammonia-fueled two-stroke engines. Promising results from full-scale engine testing gives us confidence that potentially harmful nitrogen-based emissions can be mitigated or eliminated altogether, paving the way for deployment onboard operating vessels.

Overall performance of ammonia-fueled engines in testing

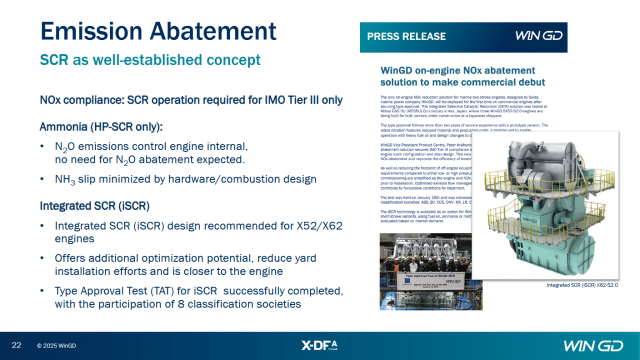

Here, we explore recent testing results from full-scale engines from engine vendors Japan Engine Corporation, MAN Energy Solutions, and WinGD. These results indicate that ammonia-fueled two-stroke engines will be compliant with IMO Tier II requirements without a DeNOX system, and compliant with IMO Tier III requirements when a DeNOX system is utilized.

Ammonia as fuel represents an immediate benefit in case of SOX emissions: depending on the pilot fuel used (and in what amount), sulphur-based emissions are reduced to near-zero, and in some cases eliminated completely. Ammonia-fueled engines will also be “overcompliant” with the CO2-equivalent emission thresholds set at MEPC 83, even with Tier 1 and on the long term.

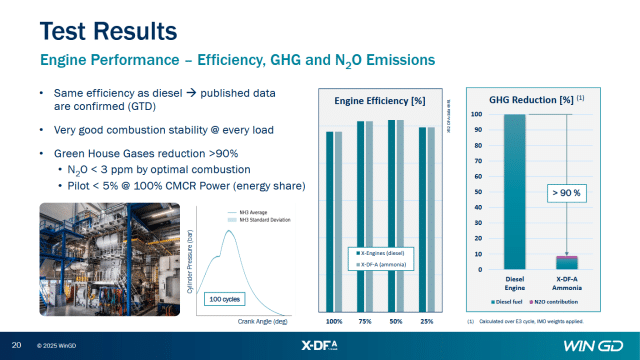

The first ammonia engines will be dual fuel, and able to operate in a diesel or fuel oil mode with the same (or better) operational performance as conventional, fossil-fueled engines. Operating in “ammonia mode”, these engines will use around 95% ammonia as a fuel on an energy basis, supplemented with 5% pilot fuel like diesel or heavy fuel oil. This is a similar amount of pilot oil used in both methanol-fueled engines and LPG-fueled engines. Full engine testing results indicate a similar thermal efficiency for “diesel mode” and “ammonia mode”.

Nitrous oxide emissions (N2O)

Click to expand. N2O emission results from full engine testing at MAN ES’ Research Centre Copenhagen. Source: MAN Energy Systems.

Nitrous oxide, or N2O, is a potent greenhouse gas, with a global warming potential (GWP) around 273 times that of CO2 on a 100 year basis. Minimizing N2O emissions from ammonia-fueled engines is therefore paramount, as highlighted in the MEPC review.

MAN indicates that nitrous oxide emissions from its test engines are “negligible”, and typically well below 5 ppm. This translates to N2O emissions less than 2% CO2-equivalent of an engine operated with fuel oil, and less than 1% CO2-equivalent of an engine operated at full load (less than 1 g-CO2e/MJ). When including the emissions from the pilot fuel oil, this results in an overall CO2-equivalent reduction of more than 90% for an ammonia-fueled engine.

Click to expand. Test results from WinGD’s full engine testing (pictured bottom left). Source: WinGD.

Meanwhile, WinGD indicates that N2O emissions for the ammonia-fueled engine are below 3 ppm, and N2O emissions less than 2% CO2-equivalent of an engine operated with fuel oil. And Japan Engine Corp generation of nitrous oxide (N2O) emissions can be suppressed to a “very low level” through “combustion controls”, with more data expected from its ongoing testing program.

Further reduction of N2O emission is envisioned through continued optimization of ammonia combustion after treatment with a dedicated catalyst. This is already proven or “off-the-shelf” technology in onshore applications, and some existing DeNOX catalysts can also eliminate N2O emissions. This will enable over-compliance with the CO2-equivalent emission thresholds set at MEPC83.

Nitrogen oxide emissions (NOX)

Nitrogen oxides, or NOX, is a combination term for the species nitric oxide (NO) and nitrogen dioxide (NO2). Nitrogen oxides contribute to the formation of acid rain and smog, while also affecting the ozone layer. NOX emissions have long been regulated across various industries and jurisdictions, and the IMO first set limits for nitrogen oxide emissions in the maritime sector in 1997 (Tier I). In 2008, the current three tier compliance system was adopted, with IMO Tier II emission limits generally applicable, and more stringent IMO Tier III limits applied to NECAs (NOX Emission Control Areas).

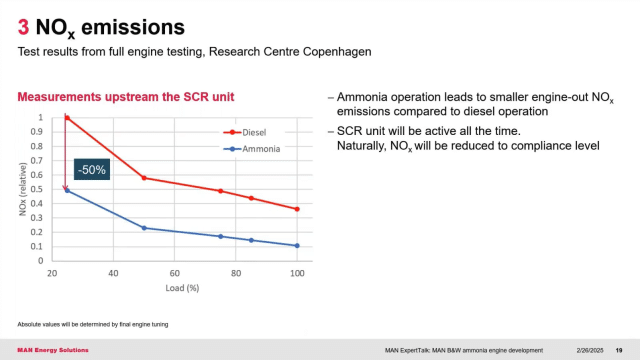

At the start of the ammonia-fueled engine development, the widely-stated aim of engine manufacturers was to be compliant with IMO Tier II without a DeNOX system, and to be compliant with IMO Tier III with a DeNOX system. Recent testing results indicate lower nitrogen oxides emissions for “ammonia mode” compared to “fuel oil or diesel mode”.

Click to expand. NOX emission results from full engine testing at MAN ES’ Research Centre Copenhagen. Source: MAN Energy Systems.

According to WinGD, nitrogen oxides emissions for ammonia operation were “well below those generated during diesel use”, with at least a 40% reduction. Similarly, MAN estimated 40% lower nitrogen oxide emissions in ammonia mode compared to fuel oil mode. Recent full engine testing at the MAN ES Research Centre Copenhagen resulted in nitrogen oxides emissions reductions of at least 50% compared to fuel oil mode. The DeNOX system required to meet IMO Tier III emission limits for an ammonia-fueled engine might actually be smaller than that required for an engine fueled by diesel or fuel oil.

Ammonia slip

The full conversion of ammonia in the engine is important for a high thermal engine efficiency, and it eliminates the risk of potentially unsafe ammonia concentrations exiting the engine (via exhaust or leaking).

According to WinGD, ammonia slip emissions in its test engines are below 10 ppm. For context, this is well below the thresholds set for ammonia leakage in the IMO Interim Guidelines for ammonia-fueled vessels: 25 ppm in enclosed spaces, and 110 ppm in secondary enclosures. According to MAN, low ammonia slip emissions are achieved through optimizing the liquid ammonia injection design and technology. Ammonia slip is typically optimized at a level just below nitrogen oxides emissions, since ammonia is used as a co-reactant to convert NOX emissions to atmospheric nitrogen (N2) and water via a selective catalytic reduction (SCR) system.

Both engine makers explored test results and commercial development progress in recent public webinars: click here to view MAN ES’ event, and here to view WinGD’s webinar.

*this article has been updated with further materials and information provided by WinGD.