Licensor selection picking up for renewable ammonia synthesis loops

By Kevin Rouwenhorst on August 20, 2024

A large number of renewable ammonia plants have been announced, with some projects taking concrete steps toward realization. One of the key steps in this process is the selection of the licensor for the renewable ammonia synthesis loop. And momentum towards project realization is building – amongst a number of developments, KBR recently announced that it had sold its tenth K-GreeN® license for a renewable ammonia synthesis loop to OCIOR Energy in India.

KBR: Licensing the 10th K-GreeN® plant

KBR delivers science, technology and engineering solutions and is one of the major ammonia licensors. According to KBR, around 50% of global ammonia production capacity uses its license for the ammonia synthesis loop.

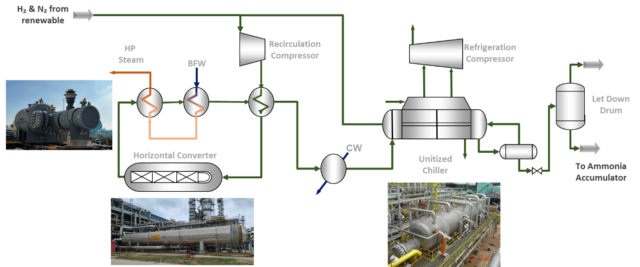

K-GreeN® technology consists of a fully integrated solution for the electrolysis of water to produce hydrogen, the separation of air to produce nitrogen and the Haber-Bosch synthesis of renewable ammonia, plus critical storage capacities (hydrogen and power when required). The KBR ammonia synthesis section is a proprietary design with demonstrated reliability and lower energy consumption at lower capital cost (due to lower equipment count). Depending on plant capacity, the synthesis section uses a vertical or horizontal ammonia converter. KBR has designed both types of converters for many plants currently in operation. The other distinctive feature of KBR’s ammonia technology is the unitized chiller, which reduces capex significantly and provides ease of operation.

K-GreeN is able to operate in a dynamic mode, and KBR claims a turndown to 10% of nominal capacity, with the ability to ramp up and down from 100% within an hour. To be able to manage dynamic operation, K-GreeN includes the Advance Process Control, an overarching control system that looks after the whole facility, including electrolyzers and an air separation unit.

KBR provides the licensed technology package with associated performance guarantees and delivery of all equipment (including ammonia converters and unitized chiller). In developing its K-GreeN concept, KBR has leveraged its 75-plus years of experience in designing ammonia plants, from very small capacity (4 tons per day) to the largest single train capacity (6,000 tons per day).

Recently, KBR sold its 10th license for a renewable ammonia synthesis loop to OCIOR Energy. A list of known KBR licenses is listed below:

- ACME: Green Hydrogen and Chemicals SPC (Oman)

- JGC: FH2R (Japan, Pilot project)

- Enaex: HyEx (Chile, Pilot project, later full-scale plant)

- Atlas Agro: Pacific Green Fertilizer Plant (United States)

- Madoqua Ventures, Power2X, CIP: MadoquaPower2X (Portugal)

- Avina Clean Hydrogen: Nueces Green Ammonia (United States)

- Lotte Chemical, Samsung Engineering, POSCO: H2biscus (Malaysia)

- Fortescue: Holmaneset Project (Norway)

- OCIOR: Gopalpur (India)

Topsoe: Licensing DynAMMO™ to NEOM

Topsoe licenses its ammonia loop for flexible renewable ammonia production as DynAMMO™. Topsoe claims a flexibility between 10% and 100%, with full ramps within minutes, and fast restarts after stand-by mode or total shutdown. The technology will be demonstrated at the REDDAP demonstration plant in Lemvig, Denmark. Known as Topsoe ModuLite Green Ammonia, small plants up to 600 tons of ammonia per day can be prefabricated rather than stick built on-site.

Topsoe has licensed the largest renewable ammonia synthesis loop so far, with a 3,500 tons ammonia per day capacity for the solar and wind project NEOM in Saudi Arabia. Other examples of synthesis loops licensed by Topsoe for renewable ammonia projects include a 1,650 tons per day loop for Project Nujio’Qonik in Newfoundland (Canada), a 1,800 tons per day loop for Mintal Hydrogen Energy Technology in Baotou (China), and a 2,500 tons per day loop for Allied Green Ammonia in Gove, Northern Territory (Australia).

Next to its activity as catalyst provider and licensor for the ammonia synthesis loop, Topsoe is also constructing a factory for solid oxide electrolyzers in Denmark, with 5 GW of capacity already secured by project developer First Ammonia.

ThyssenKrupp Uhde: Electrolysis and the dynamic uhde® ammonia synthesis technology

ThyssenKrupp Uhde is an ammonia licensor and engineering provider in the chemical industry. It has licensed its flexible ammonia synthesis loop as the dynamic uhde® ammonia synthesis technology, with capacities available from 50 up to 6,000 tons per day. ThyssenKrupp Uhde uses its RHAMFS® methodology, which includes full concept optimization from renewables up to ammonia production. With digital solutions such as the proprietary Master Controller, it is possible to turn the ammonia plant up and down between 10% and 100% to be able to follow the fluctuating availability of renewable energy inputs. ThyssenKrupp Uhde’s design offers a combination of operational flexibility and energy efficiency.

The oldest operational electrolysis-based ammonia plant in Cuzco (Peru), operated by Enaex and with a capacity of 50 tonnes per day, is based on ThyssenKrupp Uhde technology. ThyssenKrupp Uhde has not only provided licenses but actually built 4 electrolysis-based ammonia plants.

In addition to the technology licensing service, ThyssenKrupp Uhde is an experienced engineering provider, and offers delivery of fully integrated and modularized ammonia plants (including critical balance of plant and utilities). This combination of technology and deployment expertise allows ThyssenKrupp Uhde to offer performance guarantees, schedule and cost assurances, which contributes significantly to overall project de-risking.

ThyssenKrupp has conducted techno-economic studies for renewable ammonia production with an equivalent capacity of 30 million tons per annum. Examples include studies in Australia, Pakistan, Spain, the United Arab Emirates, and Vietnam. Furthermore, Pre-FEEDs and FEEDs have been performed in Australia for CIP, in Spain for Hive Energy and in South Africa for Prieska Power. Floating ammonia production concepts have also been developed for SwitchH2 and BWO.

An unique aspect of the ThyssenKrupp portfolio is that ThyssenKrupp Nucera (a sister company of ThyssenKrupp Uhde) is one of the leading OEMs for alkaline electrolyzers. More than 2 GW of electrolyzers will be supplied by ThyssenKrupp Nucera to the NEOM project in Saudi Arabia.

Casale: Flexigreen® Design for Green Ammonia Plants

Casale is an ammonia licensor known for its synthesis loop design featuring its proprietary axial-radial converter, which decreases the pressure drop and improves the performance of the ammonia synthesis loop. Casale has installed its axial-radial converter in over 250 plants, most recently using the AmoMax®-Casale catalyst jointly developed with Clariant.

Casale licenses designs for flexible, renewable ammonia plants as Flexigreen® Green Ammonia. Small-scale plants utilize the SMART-N synthesis loop, with minimum number of equipment items and relatively higher pressures, while large-scale plants utilize the FlexAMMONIA synthesis loop, allowing for optimal performance. Flexibility down to 10% of nominal load and fast load change for the ammonia synthesis capacity is claimed, in accordance with previous reporting.

Casale has licensed 12 renewable ammonia plants over the past three years. A few examples of licenses for renewable ammonia synthesis loops licensed by Casale include SkiGA (300 tons per day, Skipavika, Norway), ATOME (240 tons per day, Villeta, Paraguay), and Incitec Pivot (revamp for 1,100 tons per day, Gibson Island, Australia).

Stamicarbon: NX Stami Green AmmoniaTM for medium-scale production

Stamicarbon focuses on medium-scale ammonia synthesis loops, with capacities in the range of 50 – 500 tons per day. Stamicarbon licenses its flexible renewable ammonia synthesis loop as NX Stami Green AmmoniaTM. These ammonia synthesis loops operate at a relatively high pressure to minimize the number of equipment items in the loop for CAPEX savings, resulting in a relatively small footprint of 50 x 50 meters for a 500 tonnes per day plant.

Stamicarbon has signed the license for a 450 tonnes per day loop for the Meadowlark project of JWC Gburg in Nebraska (USA), which will be based on wind power. Stamicarbon is also the licensor of the FertigHy project for renewable fertilizer production in Northern France. Other examples include projects in Angola, Kaltim Parna Industri (Indonesia), QAFCO in Qatar, Greenfield Nitrogen (USA), and Kenya. The effect of variation in hydrogen and nitrogen feedstock will be demonstrated as well in the EU-funded INITIATE project, which will use Stamicarbon’s ammonia synthesis loop for a demo plant.