Maritime ammonia engines in Japan; ammonia shipbuilding in South Korea

By Trevor Brown on September 27, 2019

This week, Japan Engine Corporation (J-ENG) announced the launch of a new R&D program, in collaboration with the National Maritime Research Institute, that focuses on engine development for “combustion of carbon-free fuel (e.g. hydrogen and ammonia).”

Five hundred miles across the Sea of Japan, DSME has completed a techno-economic feasibility study comparing three fuels: HFO (with scrubber), LNG, and ammonia. The results of this study will be presented at the Ammonia Energy Conference, in Orlando, FL, on November 13. DSME is one of the three big shipbuilders in South Korea, and its business case for ammonia is strong enough that now “DSME is planning to expand our technology and business to NH3 engineering and systems for commercial ships.”

J-Eng and the NMRI

Japan Engine Corporation (J-ENG) has announced to cooperate with National Maritime Research Institute to start the research and development of “combustion of carbon-free fuel” (e.g. hydrogen and ammonia) as one of solutions for decarbonization …

To realize the decarbonized society that can prevent global warming through the reduction of GHG in shipping industry, J-ENG will continuously move forward to innovate and provide alternative energy solutions for future.

Japan Engine Corporation press release, J-ENG and National Marine Research Institute cooperate on the research of “combustion using carbon-free fuel”, September 24, 2019

Although the announcement discloses few details, this nonetheless represents the next step in commercialization for the ammonia engine development work that has been underway for some years at the National Maritime Research Institute (NMRI) as part of the SIP Energy Carriers program.

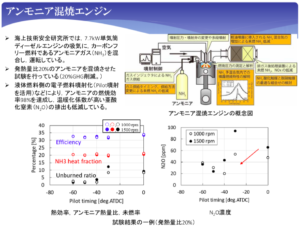

In earlier work, a diesel engine was developed to operate on a dual fuel mix of light oil and 20% ammonia (by energy content). In addition, NMRI developed an “exhaust gas aftertreatment device,” to mitigate emissions of N20, NOx, and unburned NH3.

The National Maritime Research Institute is operating a 7.7kW single-cylinder diesel engine by mixing ammonia gas (NH3), a carbon-free fuel, with the intake air.

We are conducting a test in which ammonia with a calorific value ratio of 20% is co-fired (20% GHG reduction).

Electronic fuel injection on the liquid fuel side (utilizing pilot injection) has achieved 98% ammonia combustion efficiency and reduced nitrous oxide (N2O) emissions, which have a high global warming potential …

We are investigating a combination with denitration catalyst (SCR) as a technology for unburned ammonia. It was confirmed that untreated ammonia can be significantly reduced by reducing the amount of NOx through post-treatment with a catalyst.

Koichi Hirata, Technology for reducing global greenhouse gas (GHG) emissions in the marine field, Bari-Ship 2019 presentation, May 23, 2019

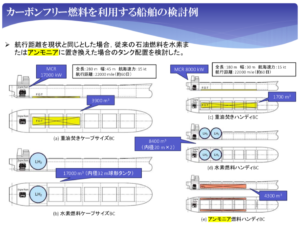

Additional work at NMRI has examined ship design from the perspective of fuel storage, which inevitably focuses on the energy density of hydrogen and ammonia relative to HFO.

To operate a 22,000 mile, 60-day journey, the conventional 1,700 m3 fuel tank would need to be replaced with 8,400 m3 of hydrogen storage, or 4,300 m3 of ammonia storage. For commercial freight operators assessing carbon-free fuels, the fact that ammonia has almost twice the energy density of hydrogen is crucial: any increase in fuel volume means a decrease in cargo capacity, which cuts away at the profit margins in an already highly competitive industry.

SIP Energy Carriers, and the Green Ammonia Consortium

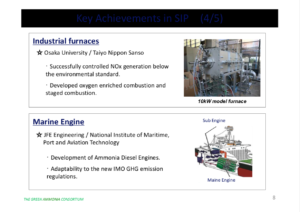

Shigeru Muraki gave the keynote presentation at the recent Ammonia = Hydrogen 2.0 Conference, hosted by AEA-Australia in August 2019. In that presentation, he discussed the achievements of the SIP Energy Carriers project, including the research strand “Marine Engine,” which focused on the “Development of Ammonia Diesel Engines.”

That project was a collaboration between JFE Engineering and the National Institute of Maritime, Port and Aviation Technology (the umbrella agency that includes NMRI). Both organizations are among the founding members of the Green Ammonia Consortium.

Muraki delivered the keynote in his new role as Representative Director of the Green Ammonia Consortium, which launched in April 2019, independent from SIP Energy Carriers.

The Consortium, whose membership now includes “More than 70 companies / institutes from Japanese and Global industries,” has the following objectives:

Objectives:

Shigeru Muraki, Green Ammonia Consortium, Ammonia, Key Green Energy for Decarbonization, keynote presentation at the AEA-Australia Ammonia = Hydrogen 2.0 Conference, August 22, 2019

- Promotion of collaborations between industry, government and academia

- Commercialization of CO2 free NH3 value chain

- Strategy & Policy making

- International collaboration

Muraki will also be giving one of the keynote speeches at the Ammonia Energy Conference in Orlando, FL, November 12 to 14. Moving beyond the achievements of the SIP Energy Carriers project, the theme of this keynote speech will be to lay out the future projects currently underway and planned by the Green Ammonia Consortium in Japan.

DSME: techno-economic study of ammonia as maritime fuel

In a separate session at the Ammonia Energy Conference, devoted to the use of Ammonia as a Fuel, Hyuk Kwon of DSME (Daewoo Shipbuilding & Marine Engineering Co., Ltd) will present the shipbuilder’s Technical & Economic Study for Commercial Ships with HFO, LNG and NH3 As Fuel.

According to the abstract for the presentation:

In this presentation, we would like to introduce the main results of a feasibility study for “Technical & Economic Study for Commercial Ships with HFO, LNG, and NH3 as Fuel.” Our goal for that study is to identify the competitiveness of ammonia compared with HFO (w/scrubber) and LNG via technical & economic analysis of NH3 …

The results of this study suggest that NH3 can be economic fuel of ships when ammonia has the competitive price via decreasing considerable cost of production and raw materials. If IMO applies more strong emission regulations on ships in the near future, the competitiveness of NH3 as a ship fuel can be increased dramatically. Finally, if infrastructure for ammonia fuel would be well equipped in the major international ports, the era for NH3 as ship fuels will be realized faster than expected. For preparing the NH3 era, DSME is planning to expand our technology and business to NH3 engineering and systems for commercial ships.

Hyuk Kwon, Mincheol Ryu, Su-Kyung An, DSME, Technical & Economic Study for Commercial Ships with HFO, LNG and NH3 As Fuel, Ammonia Energy Conference 2019

Only last week, I wrote about DNV GL’s Maritime Forecast to 2050, which describes scenarios to forecast the speed and scale of this commercial opportunity for engine manufacturers and shipbuilders. According to DNV GL’s analysis, ammonia could represent 25% of the fuel mix in 2050 and, more importantly for reaching net zero emissions (and for shipbuilders’ bottom lines), over 90% (by energy consumption) of the new ships built after 2044 would use ammonia fuel.

While DNV GL foresaw a wait of two decades before the broad adoption of ammonia as a maritime fuel, there is no missing technology that demands such a delay. Certainly, its analysis overlooked the potential of dual-fuel ammonia engines to deliver near-term GHG emission reductions while offering ship owners “fuel flexibility as a bridge towards low-carbon shipping,” and “future-proof ships” (these are terms discussed at length in DNV GL’s report). These commercial projects in Japan and South Korea point to the potential for a much more rapid implementation of ammonia as a maritime fuel than DNV GL has yet imagined.