R&D recap: the Journal of Ammonia Energy – volume II

By Geofrey Njovu on August 13, 2024

Ahead of the 3rd Symposium on Ammonia Energy set to take place in Shanghai next month, we explore the recently-published second edition of the Journal of Ammonia Energy. The open-access edition features R&D presented at the 2nd Symposium on Ammonia Energy held in Orleans, France in July 2023. You can read our recap of the journal’s first edition here.

Towards commercial applications

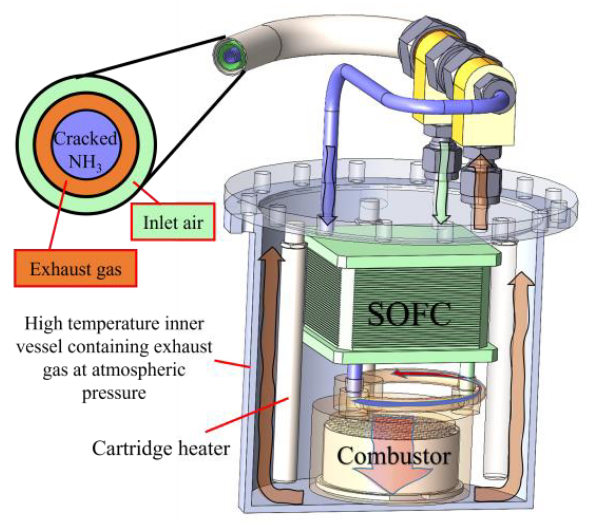

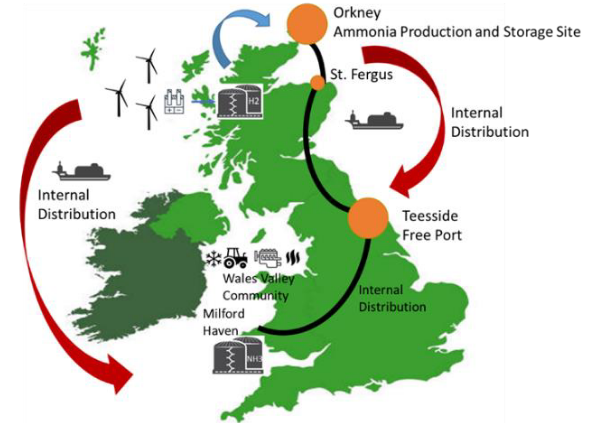

Two UK papers turn their attention towards commercial applications for ammonia. The first, by the Science and Technology Facilities Council (STFC), discusses an integrated indirect ammonia solid-oxide cell fitted with a heat exchanger and ammonia cracker, and a waste-heat recycling system. The second is a techno-economic study of renewable energy transportation in the form of ammonia or hydrogen, modelled using the Orkney Island (Scotland) as the production base, and Milford Haven Port in Wales as the destination.

Looking towards commercial deployment, the report on the health and safety roundtable highlighted that, among other things, there are a range of ongoing projects focussed on addressing ammonia safety related to its new uses. The results and learnings from these initiatives will be critical to the developing industry.

Proof of concept for waste heat utilisation in an indirect ammonia solid oxide fuel cell

Click to enlarge. Preliminary design of the integrated indirect ammonia fuel cell. From Peters et al., “An indirect ammonia fuelled solid-oxide fuel cell system with free cracking from waste heat”, Journal of Ammonia Energy 2 (2024).

Due to their high operational temperatures, solid oxide fuel cells (SOFC) present an opportunity for the recycling of high grade waste heat. In this paper presented by the Science and Technology Facilities Council (STFC), a SOFC was integrated with a heat exchanger and an ammonia cracker unit. The system (nicknamed REACH) was set up to enable heat recycled from the fuel cell to be used to power the ammonia cracker.

Prior to building and testing, the authors used Computational Fluid Dynamics (CFD) to model the system, predicting a “real world” efficiency of about 47%. The REACH (Renewable Energy Ammonia Charging) system was then built and tested, with conditions maintained auto thermally using waste heat.

Although an efficiency of about 47% was expected based on the model, only 14.35% was realised when the system was built and tested. The authors stated that the lower-than-expected actual efficiency was due to the under performance of the “off-the-shelf” fuel cell core which had a “lower fuel utilisation of 28.1% compared to the expected 85%.” They further stated that the predicted efficiency of the system would be achieved with a SOFC core performing according to the efficiency values reported in literature.

The demonstration did not include a filtering step post ammonia cracking, contrasting with similar tests performed using PEM cells. Typically PEM fuel cells require a purification step following ammonia cracking as NH3 concentrations greater than 0.1 ppm can lead to cell damage.

The paper concluded by recommending a scaled up repeat at the 10 kW scale (a 10-fold capacity increase) and with a SOFC stack that actually performs as expected. This should be followed by an in-depth assessment of the exhaust to observe NOX emissions, which was not performed in this iteration of this study. Despite the low reported efficiency of the system, the authors were confident that the proof-of-concept has been successfully demonstrated.

Marine-transported ammonia a cost effective energy vector in the UK

In this paper, the techno-economics of the transportation of renewable ammonia and hydrogen from the North of the UK to Milford Haven in Wales are analysed. The hydrogen and ammonia production modelled in the study are assumed to be powered by renewable energy (mainly wind) from the North Atlantic Ocean/North Sea. Six scenarios (A-E) were set, and used to calculate the levelized cost of hydrogen (LCOH).

- Scenario A: Hydrogen production from wind energy in Orkney and fed into a Haber Bosch unit ammonia synthesis and storage thereafter. The ammonia is then transported via ship to the Milford Haven Port where it is stored and then cracked thermally into hydrogen.

- Scenario B: Same as A, but maritime transportation from Orkney to the Teesside Free Port where it is stored and then transported via pipeline to the Milford Haven Port where it is handled exactly as in A.

- Scenario C: Hydrogen produced as in A and B but liquefied, stored and then transported via ship to the Milford Haven Port where it is stored and regasified for use.

- Scenario D: Same as in Scenario C, but transportation by ship to Teesside where it is stored and transported via pipeline to the Milford Haven Port and handled exactly as in C.

- Scenario E: As Scenario A, but with no hydrogen purification in the ammonia cracking unit.

- Scenario F: Offshore and onshore pipeline transportation of hydrogen from Orkney to Milford Haven via the St. Fergus Gas Terminal and the Teesside Free Port.

Click to enlarge. Transportation alternatives of renewable hydrogen/ammonia from Orkney to Milford Haven, Wales. From Jano-Ito and Valera-Medina, “Techno-economics of ammonia as an energy carrier. Exporting wind from the North Atlantic/North Sea to Wales”, Journal of Ammonia Energy 2 (2024).

The study found that scenario E, the use of ammonia as the energy carrier from Orkney (Scotland) to the Milford Haven Port (Wales) via maritime transportation and its decomposition back to hydrogen without purification, led to the lowest LCOH at 9.93 USD per kg of H2. This was 0.93 USD per kg of H2 and 2.53 USD per kg of H2 lower in comparison to directly transporting liquid hydrogen or considering the purification of hydrogen via ammonia, respectively.

At 11.23 USD per kg of H2, the construction of a hydrogen pipeline from Orkney to the Milford Haven Port was the next best option. Further, transporting hydrogen or ammonia via the Teesside Free Port (England) with a maritime carrier and pipeline were the most expensive alternatives.

The study shows that ammonia is a feasible large-scale energy carrier within the UK – even accounting for the use of cracking to produce hydrogen. The authors conclude that ammonia is a solution comparable to hydrogen in costs, but with better potential for rapid deployment than hydrogen due to technological maturity, especially in storage and transportation.

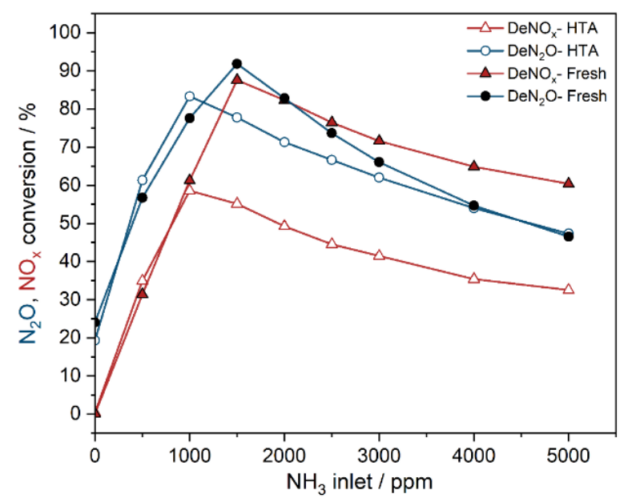

Oxygen and water are potent inhibitors of N2O and NOX conversion catalysts in NH3 engine exhausts

A significant bottleneck in the adoption of ammonia as a low carbon fuel is its exhaust emissions, which can include N2O, NOX and unburnt NH3, and high levels of water vapour. Environmentally, N2O is especially challenging due to its extremely high global warming potential relative to CO2. NH3 engines must therefore be fitted with after-treatment systems, focusing especially on ensuring low-to-zero N2O emissions.

This paper, a collaboration between the PSI Centre for Energy and Environmental Science and the EPFL Institute of Chemical Engineering, blind-tested industrial sample catalysts under conditions of N2O decomposition and of simultaneous conversion of N2O/NOX/NH3.

Click to enlarge. Impact of NH3 on the N2O and NOX conversion of pristine and hydrothermally aged industrial catalysts. From Blanco et al., “Critical aspects in the catalytic emission control of exhaust gases containing NH3, NOX and N2O”, Journal of Ammonia Energy 2 (2024).

The full results showed an intriguing mixture of interactions and demarcations between the reaction processes. Water content of ~30 vol% led to hydrothermal ageing, and in turn, a substantial negative impact on both N2O and NOX conversion. Conducting N2O decomposition and NOX reduction analysis side-by-side suggested that the two processes occur on separate active sites. And, N2O potentially promotes NOX conversion and that NH3 (a reducing agent) positively impacts N2O conversion.

To conclude, the authors stated that, although technologies are available to limit N2O and NOX emissions in the environment, their direct application to NH3 engines is complicated by the operating conditions of the engines and the presence of water, oxygen and unburnt NH3 in the exhaust. More R&D is required to develop tailored after-treatment solutions for NH3 engines to tackle both efficiency and environmental sustainability. Achieving low-temperature conversion of N2O (around 350 °C) in the presence of the complete exhaust gas mixture including NOX, N2O, NH3, oxygen and water is challenging.

Ammonia as an energy vector – health and safety

At the 2nd Symposium, an update was made to the health and safety report developed at the Cardiff meeting the previous year. A new feature of the Orleans ammonia safety report is an update on the range of activities taking place to understand the risk profile of ammonia relating to its new uses. Understanding the leakage methods, the dispersion mechanism via different media (water or airborne) will allow the implementation of evidence-based fit-for-purpose mitigation strategies.

The following studies highlight R&D focussed on understanding the hazards of ammonia handling:

- The Jack Rabbit III study coordinated by the US Department of Homeland Security and Department of Defence focuses on understanding anhydrous ammonia release. It is also looking at dry deposition of ammonia in collaboration with the University of Arkansas. Large scale tests on this work are planned for 2026-2027. In the UK, the HSE has a similar focus, building models to understand the impact of humidity on ammonia dispersion.

- The Red Squirrel trials at DNV funded by Air Products focussed on understanding the nature of leakages from both cryogenically (temperature) liquefied and pressure liquefied ammonia. This study seeks to understand the “source and dispersion characteristics” of these leakages through observing two-phase jet and liquid spills onto concrete and water.

- ARISE, a partnership between Yara Clean Ammonia, the French National Laboratory (INERIS), Maritime institute (CEDRE) and other parties in France to experimentally understand large spills of cryogenic liquid ammonia onto the sea – to determine the airborne and waterborne hazards. The trials for this are planned for 2024 – 2025.

- SINTEF, supported by funding from the Research Council of Norway, is conducting a laboratory-scale study of ammonia release onto water (includes development of models).

These projects highlight action being taken to further understanding of the unique risks associated with the use of ammonia beyond the legacy industries (fertilisers and refrigeration) into new uses as an energy vector and fuel, and from centralised large scale production to decentralised production. Public perception, development of industry standards and sharing of expertise between incumbents and new entrants also featured prominently in the health and safety discussions.