Ammonia Energy Conference 2024: Ammonia for Maritime Propulsion is full speed ahead!

By Kevin Rouwenhorst on November 26, 2024

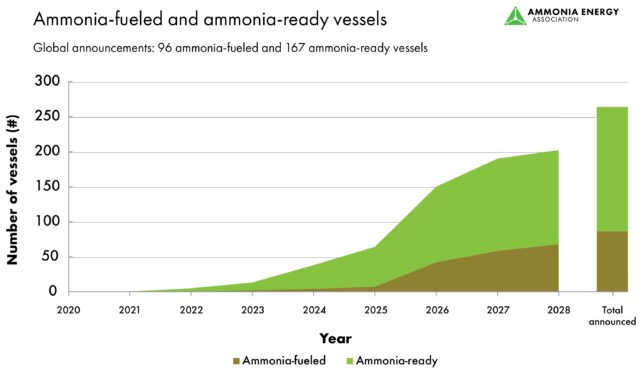

Click to enlarge. The number of ammonia-fueled and ammonia-ready vessels as of September 2024. This data is being tracked as part of the AEA’s LEAD (Low-emission Ammonia Data) project.

In 2024, a number of key demonstrations for ammonia as maritime took place. These include multiple ship-to-ship ammonia bunker transfers, and the first operations for ammonia-fueled tugboats – one with an ammonia-fueled engine, and the other propropelled by an ammonia-to-power fuel cell system. Global shipping companies have new ammonia-fueled vessels on order, with some currently under construction. Numerous “ammonia-ready” vessels are already operational, which do not currently use ammonia as a fuel, but will be able to be fueled by ammonia in the future with minimal modifications. Furthermore, the Sub-Committee on Carriage of Cargoes and Containers (CCC) at the IMO (International Maritime Organization) set interim guidelines for the use of ammonia as maritime fuel in September.

During the recent 2024 Ammonia Energy Conference, the status of ammonia as fuel for maritime propulsion was discussed, with engine manufacturers and shipowners sharing updates on their projects for ammonia-fueled vessels.

Ammonia-fueled Vessel Demonstration: From Tugboat to Midsize Gas Carrier (MGC)

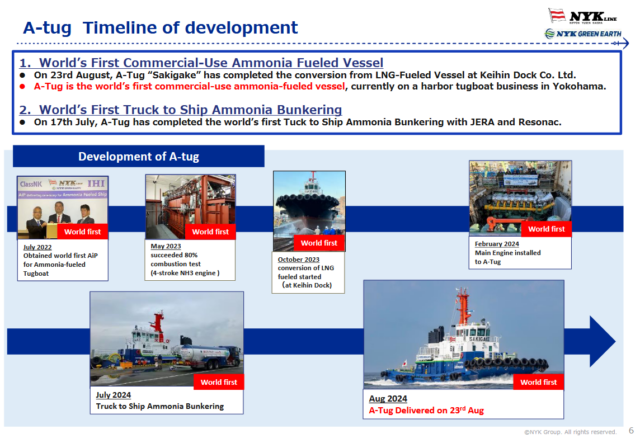

Click to enlarge. Development timeline for the ammonia-powered A-Tug, which hit the water this August. From Fumiya Fujimori, Development of Ammonia fueled vessels: Delivery of A-tug and our next plan (Nov 2024).

The NYK Line-operated tugboat Sakigake (the “A-Tug”, a retrofit of Japan’s first LNG-fueled tugboat) entered the water in August 2024, with an ammonia-fueled four-stroke engine developed by IHI Power Systems. The tugboat was (one of) the first ammonia-fueled vessels to enter the waters, and truck-to-ship fueling of the A-Tug was demonstrated at Yokohama port in July 2024. Learnings from the tugboat Sakigake are currently being used by NYK in the development of an ammonia-fueled MGC, featuring a two-stroke engine developed by Japan Engine Corporation. The midsize gas carrier is targeted for delivery in November 2026.

Ammonia engines: full-scale testing for large-scale vessels in 2026

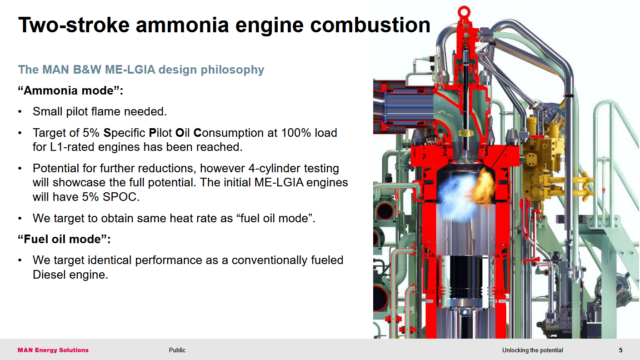

Click to enlarge. Two-stroke ammonia engine combustion at MAN ES. From Ernst Wilche, Ammonia as a fuel for two-stroke powered vessels: Unlocking the potential (Nov 2024).

Both MAN and WinGD discussed their ammonia-fueled two-stroke engines during the Ammonia Energy Conference, with the first engines to be ready for implementation by 2026. MAN reports over 12 months testing of an ammonia-fueled two-stroke test engine, with stable combustion. Around 5% of pilot oil is required for ammonia-fueled two-stroke engines, a similar fraction used for methanol-fueled two-stroke engines and LPG-fueled two-stroke engines. Nitrous oxide (N2O) emissions are virtually zero. MAN also reports 40% lower nitrogen oxides (NOX) emissions for the two-stroke engines in ammonia mode versus fuel oil mode.

Meanwhile, WinGD showcased the development chain for ammonia-fueled two-stroke engines. This started from fundamental investigations and simulations on ammonia combustion, followed by component systems testing and ongoing industrial laboratory tests. WinGD’s first ammonia combustion tests were conducted in December 2022. From this it was concluded that the injection system and combustion works appropriately, and safety systems have been approved. Next steps include the prototype testing of a first full-scale engine and subsequent field tests, which is an industry-wide collaboration with EXMAR, a leading vessel operator.

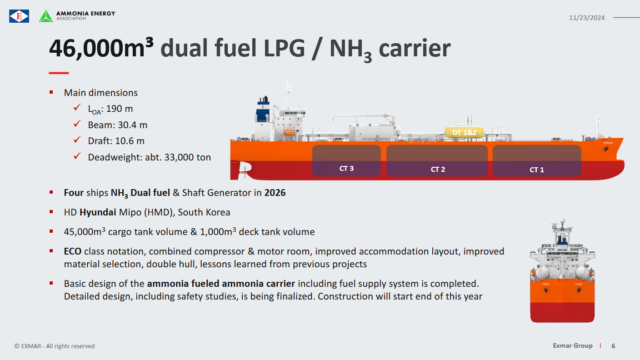

Click to enlarge. EXMAR’s 46,000 m3 ammonia-powered Midsize Gas Carrier (MGC) overview. From Kristof Coppé, EXMAR’s World’s first oceangoing Ammonia Fuelled Ships: technical update (Nov 2024).

EXMAR has an existing ammonia gas carrier business, with the largest Midsized Gas Carrier fleet in operation globally. EXMAR has recently ordered four ammonia-powered MGCs with a capacity of 45,000 m3 cargo volume each (about 30,700 tons of ammonia). Fuel ammonia will be stored in 2x 500 m3 pressurized type C storage tanks on the deck of the vessels.

Ammonia fuel supply systems and emission mitigation

Various systems have been developed for the safe transfer of ammonia from the storage tanks on the deck of the vessel to the engine, and emission management thereafter. Also, autonomous, unmanned engine rooms have been granted Approval in Principle (AiP) by classification societies, minimizing crew exposure and enhancing safety.

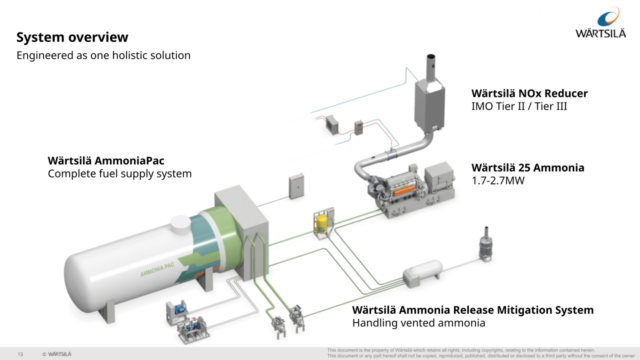

Click to enlarge. The Wärtsilä 25 ammonia engine and surrounding technology systems. From Kaj Portin, Ammonia Engine Development (Nov 2024).

During the conference, Wärtsilä discussed its multifuel four-stroke engine that can be fueled by ammonia, primarily for propulsion of small vessels. Next to this, Wärtsilä offers several other key technologies. These include an ammonia fuel supply system (AFSS) connecting Type C ammonia storage tanks to the ammonia-fueled engine, an ammonia release mitigation system (ARMS), and a DeNOX system for emission reduction from engines. Developmental testing and early operational results indicate that ammonia-fueled vessels already comply with IMO Tier II emission limits without a DeNOX system. IMO Tier III emission limits can then be achieved using the technology.

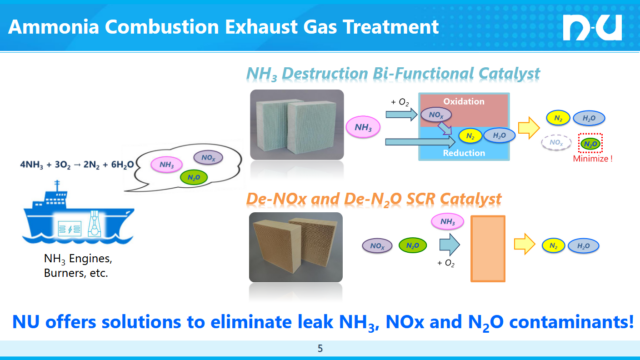

Click to enlarge. AMOX and DeNOx catalysts for emission mitigation on ammonia-fueled vessels. Source: Nikki Universal.

Emission mitigation from ammonia-fueled engines was demonstrated in 2024 by Nikki-Universal, when it supplied the catalysts for emission mitigation aboard the A-Tug. The DeNOX SCR (Selective Catalytic Reduction) catalyst converts nitrogen oxides (NOX) and nitrous oxide (N2O) with ammonia to atmospheric nitrogen and water. Nitrous oxide emissions can already be practically eliminated by engine tuning. The AMOX (ammonia oxidation) catalyst then converts any ammonia slip with oxygen to atmospheric nitrogen and water.

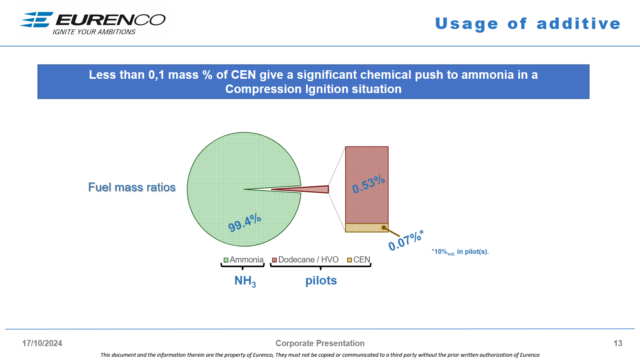

Click to enlarge. Addition of less then 0.1% mass fuel additive leads to a significant boost for ammonia combustion performance. From Anne-Gaëlle Morin, How to give a chemical push to ammonia in a compression ignition engine? (Nov 2024).

Also discussed was the addition of fuel additives to optimize ammonia combustion in maritime engines. Working in conjunction with the Prisme Lab in Orléans, EURENCO embarked on an ammonia fuel additive project that has demonstrated reduction in both ignition delay times and ignition temperature for rapid compression engines, as well as slight gains in thermal efficiency. There are also some effects on NOX emissions, though these vary by pressure. Addition of less than 0.1% mass Combustion Enhancer Nitrate (CEN) can give a significant boost to ammonia fuel in a compression engine.