Flexible ammonia synthesis: shifting the narrative around hydrogen storage

By Kevin Rouwenhorst on April 27, 2023

Renewable ammonia plants operators have a few choices. They can utilize fluctuating electricity feedstock from solar PV or wind, but can only produce when that feedstock is available. They can incorporate energy storage or hydrogen buffer storage to increase production windows. Or – as we have seen in multiple projects – grid connection can allow for a minimal electrical load throughout the day, with renewable electricity either purchased from a generator, or delivered by a low-carbon intensity grid (eg. Norway). On the other hand, existing, fossil-based Haber-Bosch plants for ammonia production are inflexible and designed to run uninterrupted at high capacity.

An example of using pressurized hydrogen storage to buffer ammonia production is the Puertollano project. The Iberdrola owned and operated plant features 100 MW solar PV, coupled with a 20 MWh battery, 20 MW PEM electrolysis capacity, and 11 pressurized hydrogen storage tanks. This feeds ammonia production at Fertiberia’s neighboring complex, displacing 8.4% of current fossil-based hydrogen feedstock.

Next to revamping existing ammonia plants with electrolysis and hydrogen storage, newbuild “flexible” ammonia technology is also under development. Several technology licensors offer flexible ammonia synthesis technology platforms that can operate down to 5 – 10% of nominal load, effectively eliminating the requirement for pressurized hydrogen storage to account for intermittency of renewables such as solar PV and wind. This is especially relevant for large-scale ammonia plants, where pressurized hydrogen storage can be a significant cost factor (even though storage units are modular). Also, large-scale pressurized hydrogen storage can be considered as a substantial safety & engineering risk, due to the high flammability of hydrogen.

The effect of flexibility

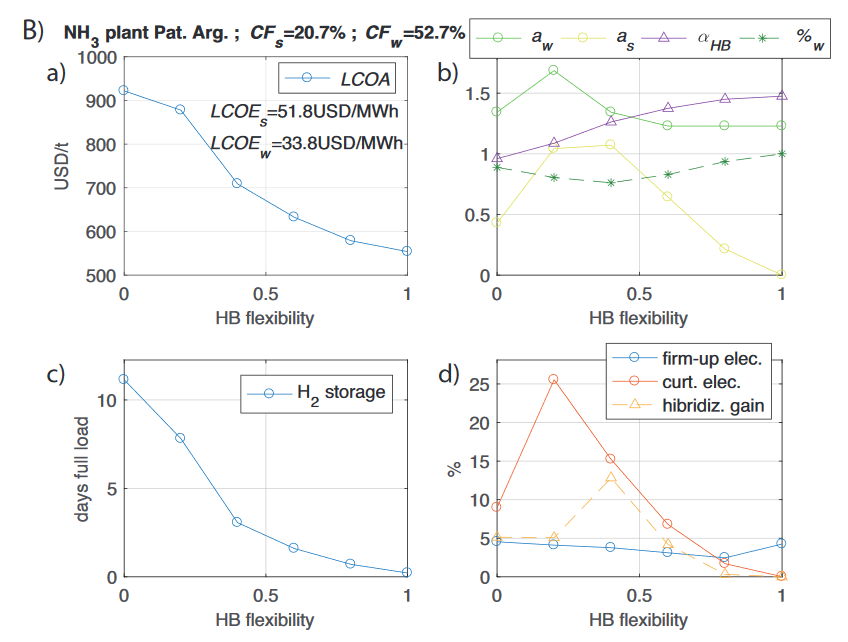

To quantify the effect of flexibility, Armijo and Philibert simulated the effect of the flexibility of the ammonia plant on the levelized cost of ammonia and the hydrogen storage requirement for various locations in Latin America. The authors found that, especially for wind-based electricity, the Haber-Bosch flexibility has a significant effect on the hydrogen storage requirement and thereby the levelized cost of ammonia.

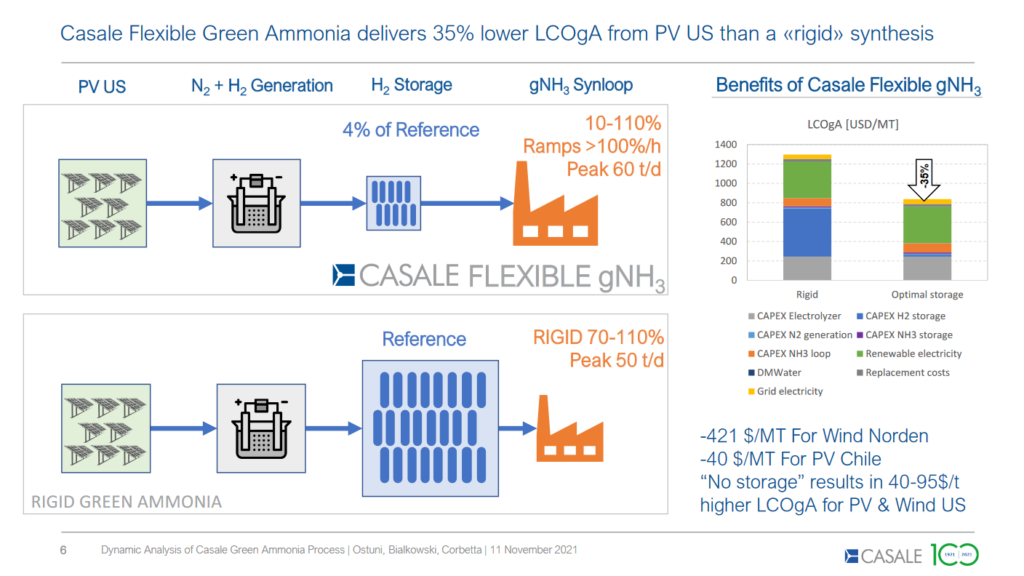

Ammonia technology licensor Casale has quantified the benefits of their flexible green ammonia technology. According to Casale, a “rigid” Haber-Bosch plant as operated for fossil ammonia production has a variable load of 70-110% of nominal capacity. Taking the USA as an example, if hydrogen production at a “rigid” plant was switched over to 100% solar PV-based, the result would be that nearly 40% (!) of total CAPEX would have to be spent on pressurized hydrogen storage. If Casale’s flexible ammonia technology is used (allowing the plant to operate at as little as 10% of nominal capacity), hydrogen storage is practically eliminated, and the levelized cost of ammonia decreases by 35%.

It should be noted that various technical advancements are required for flexible ammonia synthesis technologies. A few examples include electric heaters to maintain the temperature profile in the ammonia synthesis reactor at low operational load, variable load compressors to ramp down compression rates, and the use of surplus nitrogen as an inert to maintain the flows and pressure within the ammonia loop.

From theory to demonstration to scale-up

Currently, no commercial flexible ammonia plants are in operation. However, various projects have been announced.

Ammonia technology licensor Topsoe will be demonstrating its Renewable Dynamic Distributed Ammonia Plant (REDDAP), featuring 10 MW of electrolyzers and an annual production capacity of 5,000 tonnes of ammonia in Lemvig, Denmark by the end of 2023. Topsoe claims that this plant will be able to operate down to just 5% of its nominal capacity. Similarly, Envision Energy is currently constructing a 20,000 tonnes per year production facility with 35 MW electrolyzer capacity in Chifeng, China PR, which is planned to begin operations in September 2023.

Scale-up of flexible ammonia synthesis technology at Envision’s project already planned. By the end of 2024, the plant will expand to feature 530 MW electrolyzer capacity, producing 300,000 tonnes of ammonia per year from renewable electricity feedstock. Similarly, a flexible ammonia plant with a production capacity of 390,000 tonnes per year from onshore wind energy has been announced in Baotou, China PR, based on Topsoe’s technology. This flexible ammonia plant is expected to start production in 2025.

The size of these plants is only a few times smaller than the largest single train fossil ammonia plant (3, 670 tonnes per day, thyssenkrupp technology). These plants are intermediate steps toward renewable ammonia production at oil and gas scale – with tens of GWs of renewable generating capacity – which will be realized in the coming years. We can even look further, with plans to scale up production capacities to 10,000 tonnes of ammonia per day (3.5 million per year), as was recently announced by ammonia synthesis technology licensor KBR. These volumes are in line with the later stages proposed for renewable energy export hubs around the world, such as the AREH (Australian Renewable Energy Hub).