SMM Hamburg: pieces coming together for marine ammonia

By Julian Atchison on September 17, 2024

A number of marine ammonia announcements were made at the biennial SMM shipping conference in Hamburg this month. Developments emerged from across the entire ammonia fuel value chain, including engine deployment, fuel pumps and delivery systems, new vessel designs, and technology integration partnerships.

MAN ammonia engines: 30 vessels contracted, to be built over the next 2-3 years

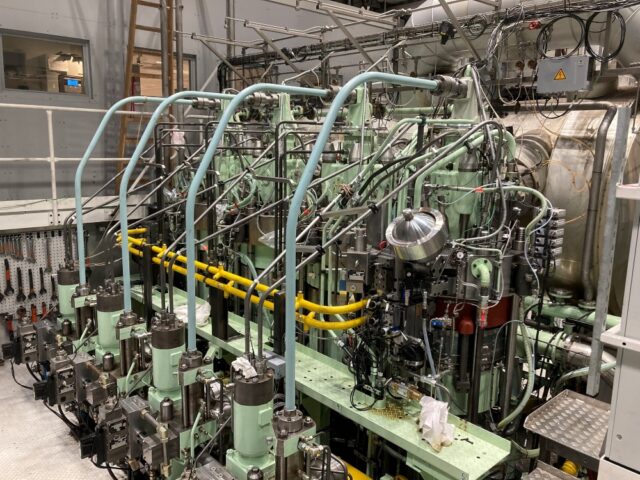

Click to listen to the interview with MAN ES’ Bjarne Foldager. MAN’s two-stroke, test engine for ammonia combustion, pictured at the Research Centre Copenhagen (RCC). Source: MAN ES.

In an interview with the Wavelength podcast on the sidelines of the event, MAN ES’ Bjarne Foldager explained that deployment of MAN’s ammonia-fueled, two-stroke engines will play out over the next two to three years. Thirty vessels are currently contracted in China, Korea and Japan, with the first to be ready in 2026 (Mitsui E&S is building the engine in Tamano, Japan for installation aboard a Capesize bulk carrier). Once operational experience is gained in 2026, MAN expects a full sales release of its ammonia-fueled engine and Foldager indicates that the organisation has already dedicated extra resources to the rollout to ensure a “positive seagoing experience” for all its first deliveries.

Fuel pumps and delivery systems

Click to learn more. Svanehøj’s new high-pressure centrifugal pump for ammonia fuel was unveiled at SMM in Hamburg. Source: Svanehøj.

Svanehøj unveiled its new HP NH3 Booster Pump in Hamburg, claiming it as the world’s first high-pressure centrifugal pump for ammonia fuel applications. Capable of delivering a fuel injection pressure of up to 100 bar, the design is based on Svanehøj’s existing deep well low-pressure fuel pump, which is set to be installed aboard a series of 210,000 dwt bulk carriers currently being built for CMB.TECH by CSSC Qingdao Beihai Shipbuilding. These bulk carriers will be powered by WinGD’s X72DF-A dual fuel engines.

The new high pressure design has a number of safety features, including hermetic sealing (no mechanical shaft seals), a containment shroud, and an additional fail-safe barrier in the event of accidental ammonia release.

We have long been encouraged by customers and partners to develop a high-pressure ammonia pump of the same high standard as our low-pressure fuel pump…Ammonia-fueled ship engines will be commercially available by 2025, and at Svanehøj, we are proud to support the energy transition of shipping by offering both low- and high-pressure pump solutions for the emerging green ammonia market.

Johnny Houmann, Chief Sales Officer at Svanehøj quoted in “Svanehøj unveils high-pressure ammonia fuel pump at SMM”, Maritime Informed, 5 Sept 2024

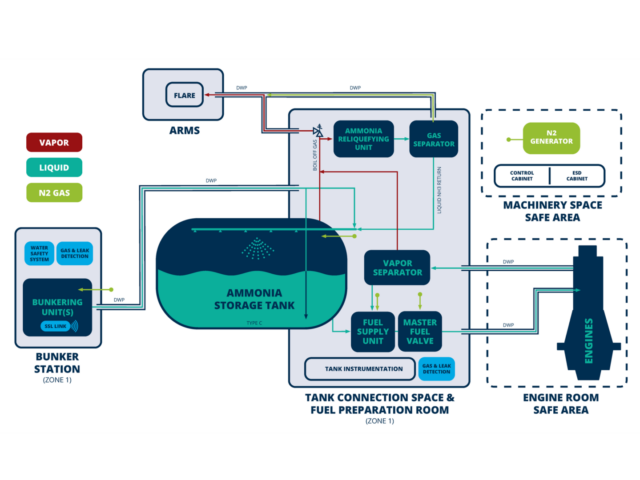

Click to expand. A schematic example of Auramarine’s new ammonia fuel delivery system, complete with a number of safety features. Source: Auramarine.

Finland-based Auramarine unveiled its new ammonia fuel delivery system. Safety measures include gas and leak detection, ammonia capture, reliquefying, and ammonia release mitigation (ARMS) functions. Suitable for two and four-stroke engines, the system was developed in conjunction with findings from the government-funded HENNES research project.

We’re already receiving interest from shipowners, operators, OEMs, and shipyards for these units, and expect to be ready for first delivery in 2026.

John Bergman, CEO at Auramarine in his organisation’s official press release, 4 Sept 2024

New vessels unveiled, AiPs awarded

DNV awarded China-based Huangpu Wenchong Shipbuilding Company (HPWS) AiPs for two ammonia-fueled designs, including a 43,000 m3 midsize gas carrier, and a 3,500 TEU container ship. The 3,500 TEU container ship will be fitted with a Type C ammonia fuel tank (can be fully or partially pressurised).

Click to learn more. Dalian Shipbuilding’s ammonia bunker vessel design has been awarded AiP by Bureau Veritas. Source: Dalian Shipbuilding.

Bureau Veritas has awarded AiP to China’s Dalian Shipbuilding for an ammonia bunkering vessel. With a capacity of 30,000 m3 of ammonia fuel, three Type C tanks will carry the bunker cargo, and an “ammonia fuel electric propulsion system” will power the vessel.

And the China State Shipbuilding Corporation unveiled the Green Sealion 20000: a 20,000 TEU ammonia dual-fuel container ship. For size perspective, CSSC also launched the world’s largest-ever container ship design in Hamburg, the Green Sealion 27500 (27,500 TEU capacity).

Amogy partners up

In a new partnership with HD Korea Shipbuilding & Offshore Engineering EP Division (HD KSOE EcoPhin), the pair will explore the integration of EcoPhin propulsion system elements (such as electrical and control systems) with Amogy’s ammonia-to-electrical technology platform. In a separate partnership with Lloyd’s Register, Amogy’s fuel-cell based system will be the subject of a decarbonisation study.