Ammonia-Powered Internal Combustion Engines

By Stephen H. Crolius on November 02, 2016

[Editor’s Note: this article written in 2016 is very popular but it’s also somewhat outdated now. If you seek information on the latest research and development, please refer to our archive for the topic: Ammonia Internal Combustion Engine.]

Ammonia energy proponents look forward to the day when their fuel is used in internal combustion engines – but the state of this art is unsettled and it is not clear which combustion technologies will win in the end.

This lack of clarity notwithstanding, consensus prevails about the technical challenges that an ammonia engine must overcome. The Caterpillar Corporation put it succinctly in their 2008 patent application that covers a “power system having an ammonia-fueled engine”: “When ammonia is combusted, the combustion produces a flame with a relatively low propagation speed . . . This low combustion rate of ammonia causes combustion to be inconsistent under low engine load and/or high engine speed operating conditions. Most existing combustion engines that use ammonia as engine fuel typically require a combustion promoter (i.e., a second fuel such as gasoline, hydrogen, diesel, etc.) for ignition, operation at low engine loads and/or high engine speed.”

In other words, one option is to use a liquid combustion promoter. However, as the patent subsequently notes, this approach “generally requires dual fuel storage systems, dual delivery systems, and dual injection systems, thus adding additional weight, complexity, and cost to the engine system.”

The second option is to use hydrogen as the combustion promoter. A promising variant of this approach is to place an on-board reformer between the fuel tank and the engine. The reformer can be set up to “crack” enough of the ammonia into hydrogen and nitrogen to support viable combustion. Crackers can be simple in mechanical terms, consisting of a heated chamber furnished internally with a catalyst. However, the patent describes one more challenge: “The requirement for the combustion promoter fuel fluctuates with varying engine loads and engine speed, which can cause control issues.” This means that cracking a fixed proportion of the ammonia (or a proportion that varies simply with the rate of fuel flow) is unlikely to produce good engine function.

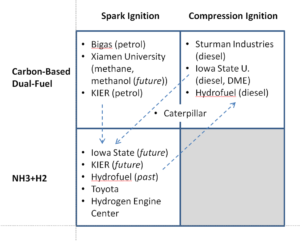

AmmoniaEnergy has assembled data on nine current and recent ICE development programs. They are about evenly distributed across three camps.

First there are the carbon-based dual-fuel players working with spark-ignition systems. These include Bigas International and the SAVIA coalition of Italy; the Green Transportation Technology Group at the Korean Institute for Energy Research; and the ammonia research group at Xiamen University in China.

Next there are the carbon-based dual-fuel players working with compression-ignition systems. These include Sturman Industries (whose ALL-ternative engine was recently profiled by AmmoniaEnergy); Hydrofuel Inc. of Canada; and Song-Charng Kong’s program at Iowa State University. Caterpillar’s patent implies the use of a secondary fuel that is not hydrogen, but is silent on which ignition method might be employed.

Finally, there are the players who are using hydrogen as the combustion promoter. These include Toyota’s Central R&D Labs; and the Hydrogen Engine Center of Iowa in the U.S.

Based on the identity of the players and level of activity in each quadrant it is not obvious which approach is likely to win over the long run. One observation that can be made, though, is that most of the players in the top quadrants have stated plans to migrate away from fossil fuels as combustion promoters. This may involve “dropping in” a sustainable version of the secondary fuel, such as biodiesel. Or it may involve migrating from a fossil fuel to a different fuel that can be produced sustainably, such as dimethyl ether (DME). Or it may involve exiting carbon-based secondary fuels altogether and migrating into NH3/H2 quadrant.